-

-

Using your Testo analyzer, run a combustion analyzation test.

-

Stack temperature should be between 350 to 450 degrees fahrenheit.

-

O2 Percentage should be between 3-10% depending on the type of boiler.

-

Carbon monoxide parts per million (ppm) should be between .1 to 10 ppm.

-

Gross Efficiency should be between 85-95%

-

-

-

Remove each burner tube and inspect for damage and wear and tear.

-

Burner tubes rarely need to be replaced but they should be removed for inspection every time maintenance is performed.

-

-

-

For Steam Boilers Only

-

Verify the low water cutoff is functioning properly. If the green and red indicator lights are flashing that indicates the low water cutoff has an error.

-

Press the red reset button to reset the low water cutoff. That should resolve any errors.

-

-

-

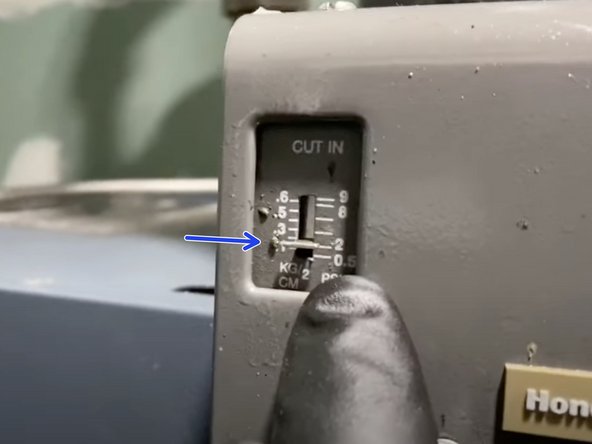

The pressure controller should be set to 1.0 PSI for low-pressure boilers.

-

Any errors or ideas for improvement should be submitted via comments.

Any errors or ideas for improvement should be submitted via comments.